How to use:

DTF film:

First, Use a DTF printer to print graphics for DTF Film.

Then cover your print with DTF hot melt powder, make sure that the j glue powder sticks to the pattern evenly

Put the baking pet film into the oven to bake the picture, the temperature is 110°, and the baking time is 150-180 seconds. After baking, al.l the rubber powder on the pattern needs to be melted, and the pattern does not crack.

For heat transfer, the clothes need to be ironed first, and then put the pattern on the position where the clothes need to be hot stamped for hot stamping. The temperature of hot stamping is 160° and it needs to be pressed for 20 seconds. The press is 5 KG, Slowly tear off the film.

Printable vinyl:

First, print the pattern on the white film, and then cut it into small pieces according to the shape. After the waste is discharged, use a cold laminator to cover the pattern surface with a layer of PET, and finally cut it out and iron it. The temperature of hot stamping is 135-145°C and it needs to be pressed for 12-15 seconds. The press is 4-6 KG, warm or cool peel is OK.

Advantages of DTF:

- Use special white ink, high color fastness, environmental protection and health.

- No need for plate making and transfer.

- No engraving, no hollowing out, no waste discharge, saving time. Reduce labor costs.

- High-definition color reproduction

- DIY personalized customization

- The color is real and clear, and it is not easy to fade.

Disadvantages of DTF:

- The quality of the transparencies determines whether the colors are bright or not.

- The material has no tensile force and is not breathable.

- Shaking powder is not clean, local sticky powder.

Advantages of printing film:

- The thickness of the main film is 0.1mm, the hand feel is soft and elastic, and the air permeability is good after ironing.

- PET rubber bottom, 0.11mm thickened PET bottom, cutting plotter is easier, and waste disposal is simple and convenient

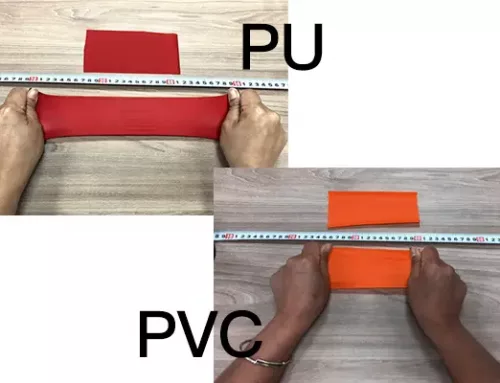

- Soft and anti-stretching, the main film is made of PU material, soft to the touch, no cracking when stretched, good air permeability, washable

- Easy to engrave, easy to tear, easy to deal with small letters, with positioning film, easy to transfer, warm and cold tearing after hot pressing.

- Bright color, strong color fastness and high color reduction.

- Environmentally friendly materials, no adverse reactions in contact with the skin, no harm to the skin.

Disadvantages of printing film:

- The line requirements of the individual pattern are relatively rough. If it is too thin, the cutting plotter cannot cut out a complete pattern.

- It is necessary to use a cold laminating machine to coat a layer of PET on the surface of the printing film, otherwise it will not be well pressed.

- Need to use weak solvent ink, ordinary ink is not suitable.

How to choose DTF film or printing film

1. The thickness of the lines of the letter pattern

The lines are too thin, consider printing with DTF film

If the line spacing is greater than 1.2mm, the cutting machine can easily cut it, and printing film can be considered

2. Requirements for quality

If the definition is not high, you can consider DTF film printing

High definition is required, consider making printing film, and the color reproduction degree is higher.

3. How much is the quantity

Large quantity, low cost to do DTF

The quantity is small, you can consider making printing film.