Flocking heat transfer vinyl is a very common and popular processing method in the garment printing industry. This printing process has the following characteristics:

1.Bright colors, rich colors, a variety of options.

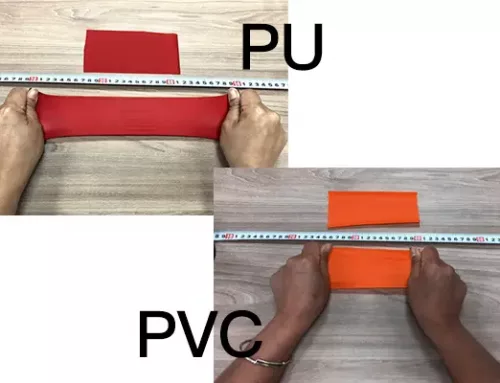

2.The thickness is suitable The thickness is only 0.5-0.6mm, which is convenient for cutting machine and laser machine processing.

3.Selection of raw materials Using high-quality suede, flocking density is good, soft to the touch. Using environmentally friendly materials, no harm to the skin.

4.Good breathability, waterproof and breathable, can be used for jerseys and summer clothing, breaking the design of conventional lettering membranes.

5.The coloring is firm, soft and does not crack, resistant to UV rays and sunlight, and can be machine washed without fading.

The difference from traditional flocking heat transfer:

The traditional flocking printing is done by the method of screen printing. The special flocking pulp is repeatedly scraped on the substrate through the flocking screen printing plate. Each scraping must be dried and repeated, and then the heat transfer machine will transfer the paste. The fluff from the flocked paper is transferred to the substrate.

This processing technology is only suitable for professional large and medium-sized printing factories for mass printing due to its complex process, high technical requirements, high cost and high working hours.

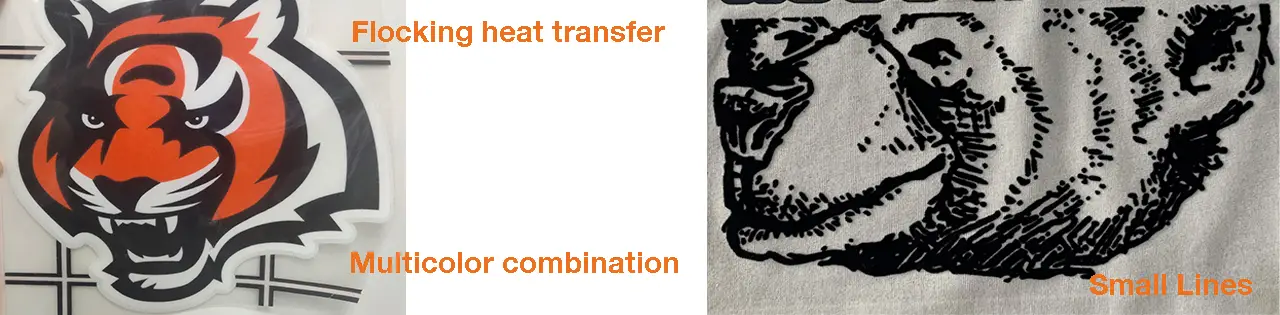

The traditional flocking printing is suitable for: multi-color combination of patterns and letters or lines are too thin to be used for cutting machine or laser machine cutting. This process of flocking heat transfer can be done.

Disadvantages: 1. Need to open the mold, need to increase the version fee, and need to start the fee when the number is small.

- The fluff is not as three-dimensional as the flocking lettering film, and the fluff is not as soft as the flocking lettering film.

- Small batch or personalized flocking design cannot be satisfied.