About heat transfer lettering film, series of ordinary colors, I believe many people do not know much about the material. Today, let’s talk about it briefly. If there is any unreasonable place, please bear with me.

Same :

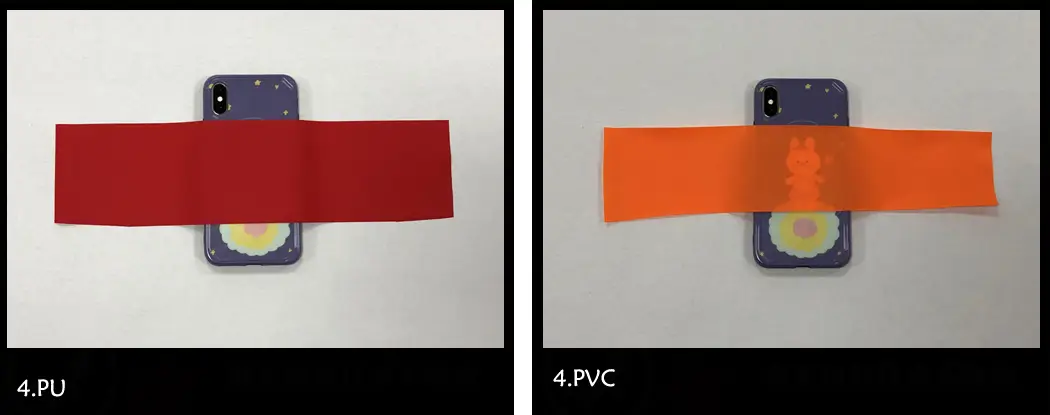

- The color is basically the same.

From the appearance, the color can be basically the same, and the picture can’t tell whether the material is PU or PVC. Even in terms of description, it will not deliberately emphasize whether it is PU material or PVC material.

- It can be ironed and pressed on the textiles of clothing, luggage and bags.

- They are all matte materials.

- The PET protective film has the function of sticking back.

- Both cold tear and warm peel are acceptable

- Can be ironed by pressing machine or iron.

- Clothes with waterproof coating, metal products, ceramics, plastics, and wooden products cannot be ironed.

difference:

- Lettering fluency problem

PU lettering is smooth, cutting lines are smooth, and the main film is easy to cut through

The lettering of the PVC part is not smooth, and the main film is not easy to be carved through

- Laser machine engraving problem

PU can use laser machine to engrave small characters, smooth and no problem

PVC laser machine engraving small characters is easy to be damaged and not smooth.

- Material softness

The PU material feels soft and silky.

PVC material is hard and not flexible

- Translucent problem

The PU material is added with an anti-transparent layer, which will not reveal the background color of the clothes

The PVC material does not have an anti-transparent layer, which is easy to reveal the background color of the clothes and affects the finished effect of the clothes.

- The thickness of the material

The thickness of PU material is 0.1mm, plus and minus tolerance 0.01mm, light and thin.

The thickness of the PVC material is 0.12mm, which is slightly thicker. After ironing, it will increase the heaviness of the clothes.

- Material surface appearance problems

The color layer on the surface of the PU material is a matte surface, which is made by using the latest coloring technology in multiple processes.

The surface of the PVC material adopts the old roller painting technology, which makes the surface of the main film show fine lines. Not smooth to the touch.

- The problem of stretching force

The PU material has good tensile force and can be ironed on elastic fabrics.

PVC material has no tensile force and cannot be ironed on elastic fabrics.

- Problems with repositioning after stretching

The PU material is only slightly deformed after stretching, which will not affect the effect of the finished product.

The PVC material will deform after stretching, which will affect the beauty of the clothes.

How to choose PU or PVC material

1. Price demand

The price of PVC is cheaper than that of PU, and different prices can be selected for different customer groups.

2. Market demand

PU material is environmentally friendly, and the market where the customer is located has strict requirements on testing, so PU material can be selected.

3. Quality requirements

The washing fastness of PU has reached more than 40 times. Generally, big brands have strict requirements on washing fastness, and PU materials can be selected.

There are many varieties on the market and the quality is uneven, but we will insist on making products with high cost performance and choose the best solution for customers. Achieve win-win.